Sand. Made up of 25 percent silicon, is, after oxygen,

the second most abundant chemical element that's in the

earth's crust. Sand, especially quartz, has high percentages

of silicon in the form of silicon dioxide (SiO2) and is

the base ingredient for semiconductor manufacturing.

After procuring raw sand and separating the silicon,

the excess material is disposed of and the silicon is

purified in multiple steps to finally reach semiconductor

manufacturing quality which is called electronic grade

silicon. The resulting purity is so great that electronic

grade silicon may only have one alien atom for every one

billion silicon atoms. After the purification process,

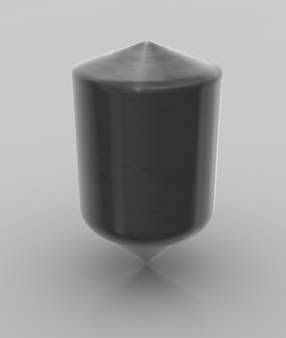

the silicon enters the melting phase. In this picture

you can see how one big crystal is grown from the

purified silicon melt. The resulting mono-crystal

is called an ingot.

A mono-crystal ingot is produced from electronic grade

silicon. One ingot weighs approximately 100 kilograms

(or 220 pounds)and has a silicon purity of 99.9999 percent.

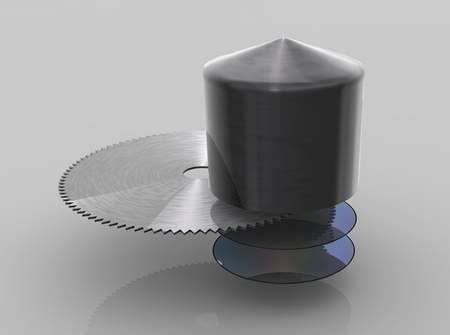

The ingot is then moved onto the slicing phase where

individual silicon discs, called wafers, are sliced thin.

Some ingots can stand higher than five feet. Several

different diameters of ingots exist depending on the

required wafer size. Today, CPUs are commonly made

on 300 mm wafers.

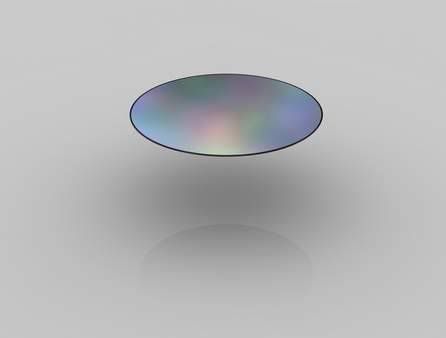

Once cut, the wafers are polished until they have flawless,

mirror-smooth surfaces. Intel doesn't produce its own ingots

and wafers, and instead purchases manufacturing-ready

wafers from third-party companies. Intel’s advanced

45 nm High-K/Metal Gate process uses wafers with a

diameter of 300 mm (or 12-inches). When Intel first

began making chips, it printed circuits on

50 mm (2-inches) wafers. These days, Intel uses 300 mm wafers,

resulting in decreased costs per chip.

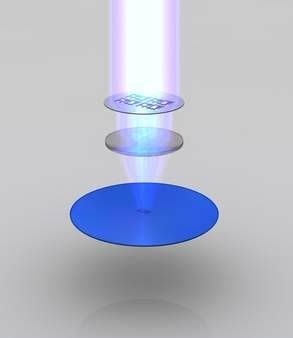

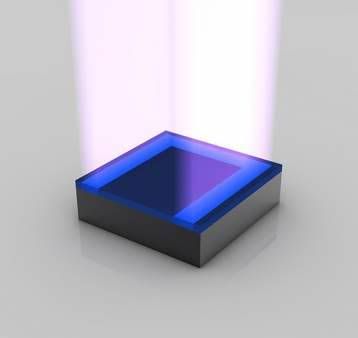

The blue liquid, depicted above, is a photo resist finish similar

to those used in film for photography. The wafer spins during

this step to allow an evenly-distributed coating that's smooth

and also very thin.

At this stage, the photo-resistant finish is exposed to ultra

violet (UV) light. The chemical reaction triggered by the UV

light is similar to what happens to film material in a camera

the moment you press the shutter button.

Areas of the resist on the wafer that have been exposed to UV

light will become soluble. The exposure is done using masks

that act like stencils. When used with UV light, masks create

the various circuit patterns. The building of a CPU essentially

repeats this process over and over until multiple layers are

stacked on top of each other.

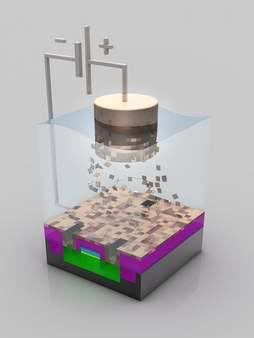

A lens (middle) reduces the mask's image to a small focal point.

The resulting "print" on the wafer is typically four times smaller,

linearly, than the mask's pattern.

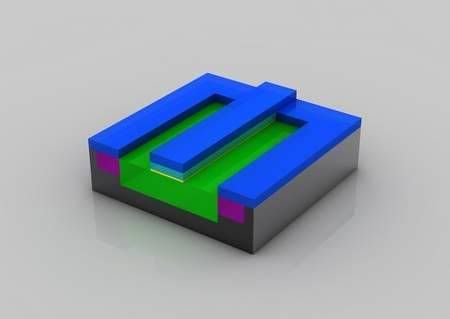

In the picture we have a representation of what a single

transistor would appear like if we could see it with the naked eye.

A transistor acts as a switch, controlling the flow of electrical

current in a computer chip. Intel researchers have developed

transistors so small that they claim roughly 30 million of

them could fit on the head of a pin.

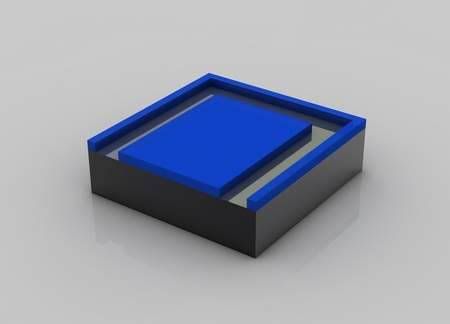

After being exposed to UV light, the exposed blue photo resist

areas are completely dissolved by a solvent. This reveals a

pattern of photo resist made by the mask. The beginnings of

transistors, interconnects, and other electrical contacts

begin to grow from this point.

The photo resist layer protects wafer material that should

not be etched away. Areas that were exposed will be etched

away with chemicals.

After the etching, the photo resist is removed and the

desired shape becomes visible.

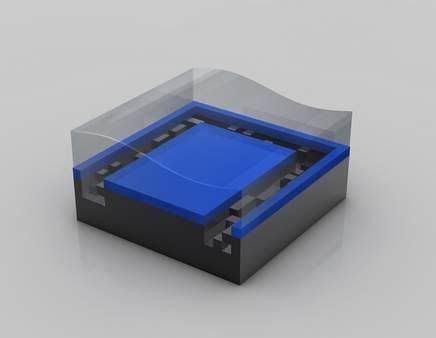

More photo resist (blue) is applied and then re-exposed to

UV light. Exposed photo resist is then washed off again

before the next step, which is called ion doping.

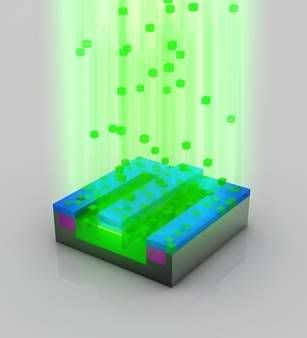

This is the step where ion particles are exposed to the wafer,

allowing the silicon to change its chemical properties in

a way that allows the CPU to control the flow of electricity.

Through a process called ion implantation (one form of a process

called doping) the exposed areas of the silicon wafer are

bombarded with ions. Ions are implanted in the silicon wafer

to alter the way silicon in these areas conduct electricity.

Ions are propelled onto the surface of the wafer at

very high velocities. An electrical field accelerates

the ions to a speed of over 300,000 km/hour(roughly 185,000 mph)

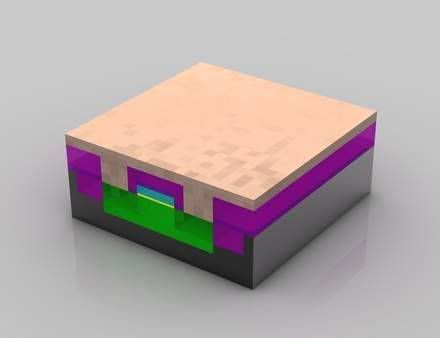

After the ion implantation, the photo resist will be removed

and the material that should have been doped (green) now has

alien atoms implanted.

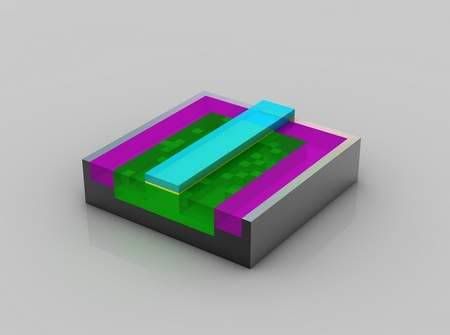

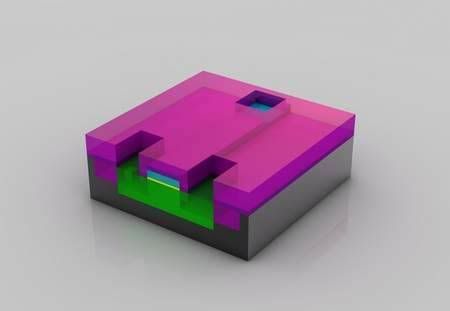

This transistor is close to being finished. Three holes have

been etched into the insulation layer (magenta color) above

the transistor. These three holes will be filled with copper,

which will make up the connections to other transistors.

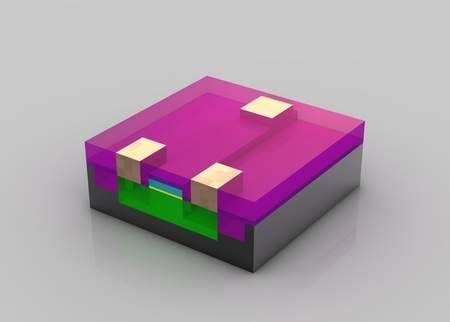

The wafers are put into a copper sulphate solution at this stage.

Copper ions are deposited onto the transistor through a process

called electroplating. The copper ions travel from the positive

terminal (anode) to the negative terminal (cathode)

which is represented by the wafer.

The copper ions settle as a thin layer on the wafer surface.

The excess material is polished off leaving

a very thin layer of copper.

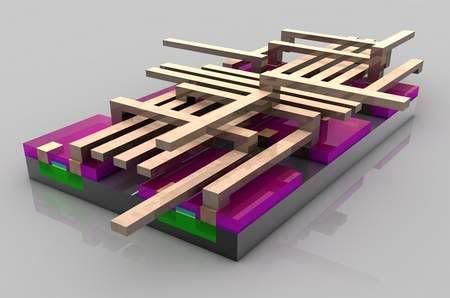

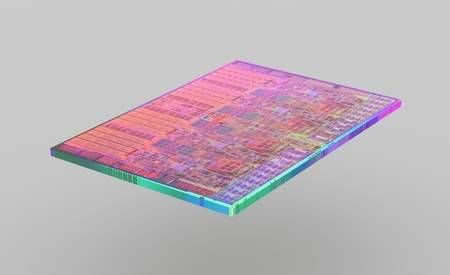

Multiple metal layers are created to interconnects (think wires)

in between the various transistors. How these connections have

to be “wired” is determined by the architecture and design

teams that develop the functionality of the respective processor

(for example, Intel’s Core i7 processor). While computer chips

look extremely flat, they may actually have over 20 layers to

form complex circuitry. If you look at a magnified view of a chip,

you will see an intricate network of circuit lines and

transistors that look like a futuristic, multi-layered

highway system.

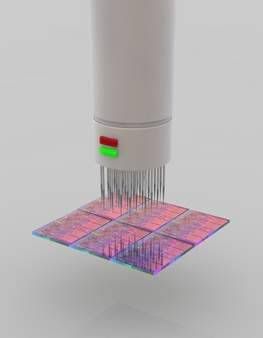

This fraction of a ready wafer is being put through a first

functionality test. In this stage test patterns are fed into

every single chip and the response from the chip monitored

and compared to "the right answer."

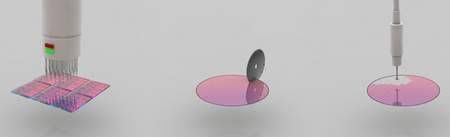

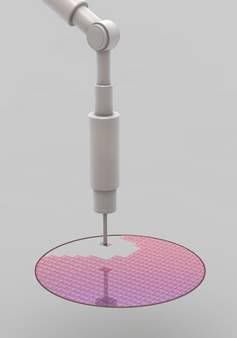

After tests determine that the wafer has a good yield of

functioning processor units, the wafer is cut into pieces

(called dies).

The dies that responded with the right answer to the test

pattern will be put forward for the next step (packaging).

Bad dies are discarded. Several years ago,

Intel made key chains out of bad CPU dies.

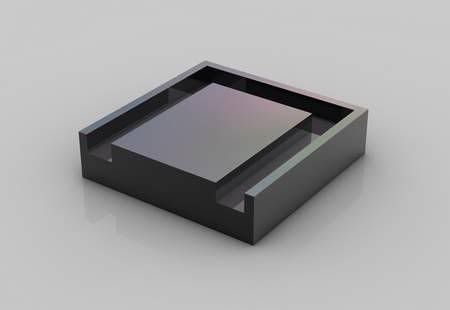

This is an individual die, which has been cut out in the

previous step (slicing). The die shown here is a die of

an Intel Core i7 processor.

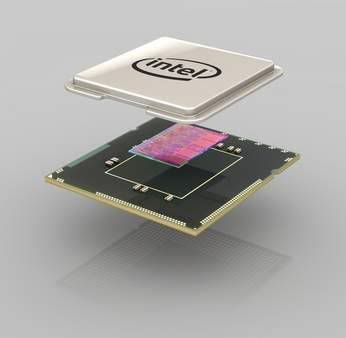

The substrate, the die, and the heatspreader are put

together to form a completed processor. The green

substrate builds the electrical and mechanical interface

for the processor to interact with the rest of the PC

system. The silver heatspreader is a thermal interface

where a cooling solution will be applied.

This will keep the processor cool during operation.

A microprocessor is the most complex manufactured product

on earth. In fact, it takes hundreds of steps and only

the most important ones have been visualized in this

picture story.

During this final test the processors will be tested for

their key characteristics (among the tested characteristics

are power dissipation and maximum frequency).

Based on the test result of class testing processors with

the same capabilities are put into the same transporting trays.

This process is called "binning". Binning determines the maximum

operating frequency of a processor, and batches are divided

and sold according to stable specifications.

0 comments:

Post a Comment